What is the Henkelman Advanced Control System?

Unleashing the full potential of your Commercial Food Service Operation with Henkelman Advanced Control Systems.

What is the Henkelman Advanced Control System?

The Henkelman Advanced Control System is the latest technology in the commercial foodservice chamber vacuum sealer industry and opens the door to endless possibilities for foodservice operations of every size.

Let's take a look at the extensive list of features and benefits that extend the shelf life of food products and ultimately increase your bottom line! You'll see us mention it time and time again throughout our content, but we really can't understate the benefit of a Henkelman vacuum packaging machine — especially those that come standard with a CombiVAC ACS control panel.

CombiVAC Is The Standard

Advanced Control Systems come standard equipped on all Henkelman CombiVAC units including Boxer, Marlin, and Polar units. ACS panels make Henkelman machines the perfect accessories to every commercial operation regardless of your operation's function.

Schools, Grocers, Hospitals, and Food Processors alike can realize measurable ROI in their commercial food service operation as the unit makes food packaging simple, manageable, and scalable!

A Henkelman that's standard equipped with ACS allows you to meet the challenges of day-to-day operations and strategy while your Henkelman CombiVAC machine simplifies operations tasks like managing stock, and quality, and helps to ensure that food is kept at safe and compliant levels with HAACP data tracking.

- Extend Shelf Life

- Track HAACP Data

- Custom Smart Kitchen Programs

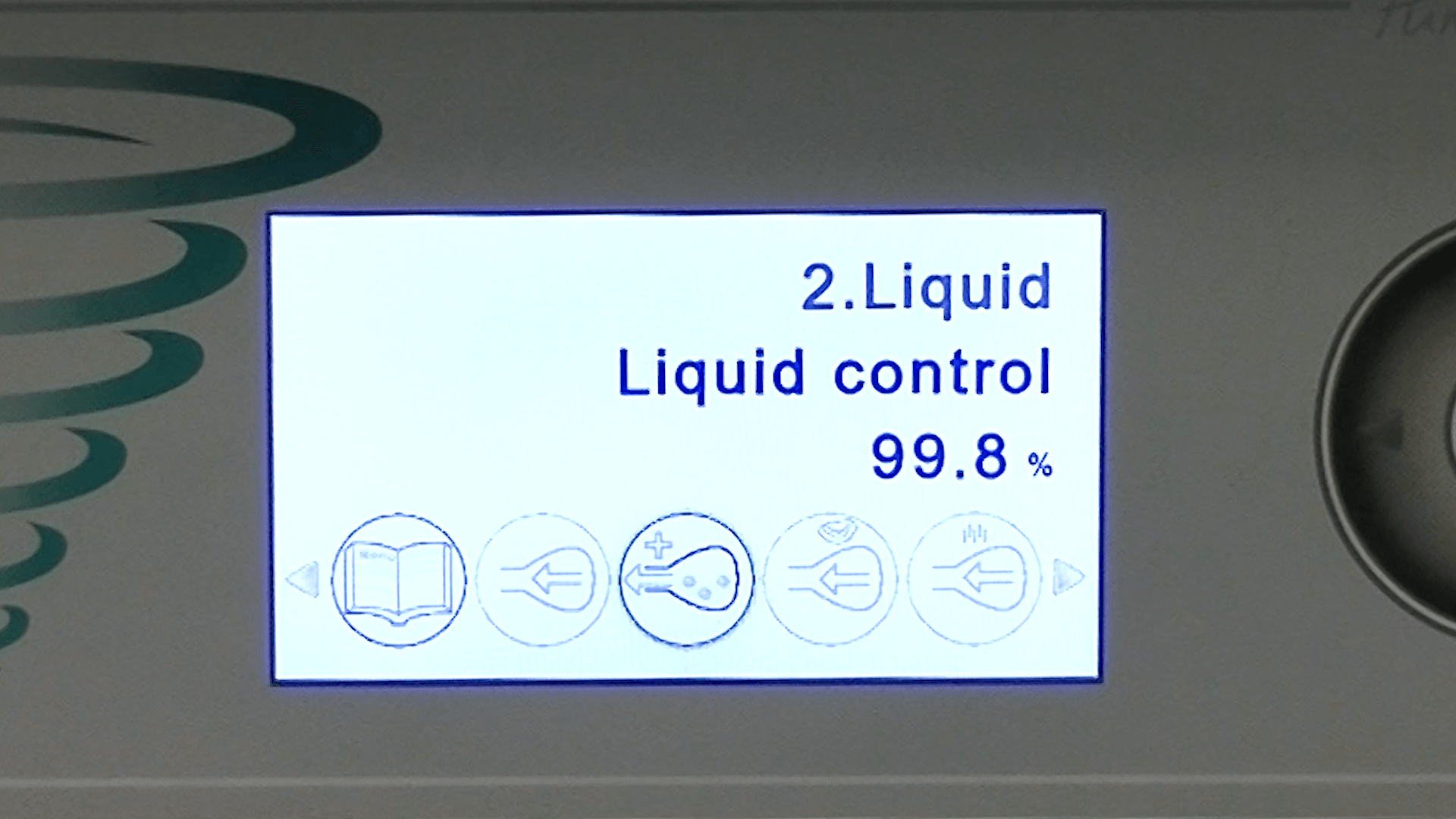

- Easy Navigation and LCD Menu Display

Monitor your vacuum cycle progress in real-time on the bright and legible LCD display from Henkelman! With push buttons that allow you to search through program history and functions even with fingers covered in cake batter!

Menu Structure

Featuring an extensive menu structure with numerous capabilities you're sure to find your new favorite vacuum cycle function in one of the preset programs including — Red Meat Function, Marinating Function, Sequential Vacuum Function, and much more.

Can't find what you're looking for in the default programs?

Custom Programs

With the ability to create custom programs that allow complete control of vacuum percentage and sequence you'll be able to use techniques like soft air seal which helps to protect food packaging from sharp objects without puncture!

Label Printing and External Programming

Directly connect a label printer and Henkelman unit! When a Henkelman is combined with a label printer and a computer this allows for easy programming from your computer to adjust a variety of options like:

- 20 Saved Programs

- 90 Product Labels

- Adjust Program Names

- Tune Vacuum Cycles

- Customize Contents Labels

- Add Customer IDs

Seafood Processor with Soft Air and ACS

Let's imagine you're a large-scale Seafood Processor buying lobster tails!

With the purchase of a Henkelman Polar unit and a label printer, you've now unlocked the capability to develop a program with set parameters for vacuum-sealing lobster tails at scale!

- Create a custom soft air program to prevent packaging puncture from sharp lobster tails

- Connect a label printer that generates labels for tracking important packaging history like item contents, date, and suitable storage conditions.

- Extend shelf life and use a GreenVAC Vacuum Seal Bag for cold storage.

- Clean your Henkelman unit when it tells you to!

- Even display vital Serve Safe information regarding the temperature and suggested storage length.

As a large-scale operation, it's important that you have complete control over your vacuum packing and food product quality and it's crucial that operations be repeatable.

Take back control of your commercial operation and make it easy to focus on providing superior service with Henkelman!

In Conclusion

Once you've purchased a Henkelman unit with CombiVAC and ACS control it's hard to imagine a world without it.

Whether it's a tabletop vacuum unit like a Henkelman Boxer, a single chamber floor unit in the Marlin, or a double chamber vacuum machine like the Polar series from Henkelman — you're sure to benefit from extending stock shelf life, preserve food container integrity, and relieve the pressure off your labor force by leveraging the power of Henkelman CombiVAC with an Advanced Control System.

Check with your local MFC rep about product information, and options!