Vacuum Sealers & CombiVAC Machines

All units come standard with industry leading Busch vacuum pumps.

Vacuum Sealers & CombiVAC Machines

Invacus is the exclusive North American importer for Henkelman commercial vacuum sealers.

Invacus offers expert sales support and product knowledge for the full line of countertop, floor, and industrial commercial vacuum sealer machines from Henkelman.

We specialize in food service applications.

Choose between an intelligent CombiVAC packaging machine for complete control and advanced function, or keep it simple with JumboVac — our most fundamental vacuum sealer series.

All units come standard with industry leading Busch vacuum pumps.

Which vacuum sealer solution do you need?

Choose your series:

AERO

series

Standard with Soft Air & Liquid Control

State of the art, innovative, robust machine with a slick design. Easy control interface. 3 adjustable setting programs. Standard Soft-air. Precise vacuum settings with sensor pressure control. This table-top model complies with CE/UL/ETL standards.

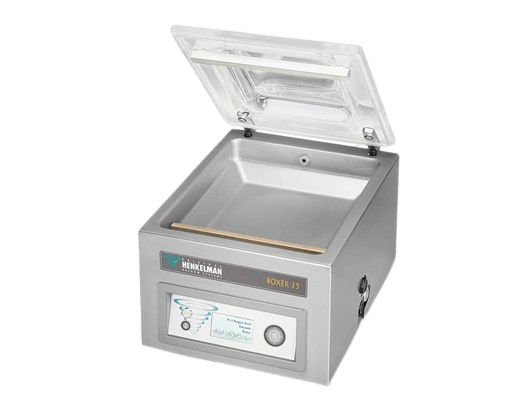

BOXER

series

Standard with CombiVAC ACS controls

The Henkelman Boxer countertop series comes standard with CombiVAC technology including a 20 program memory, full color screen and a USB connection. All units are HACCP compliant and compatible with a direct label printer.

MARLIN

series

Optimal Capacity + Attractive Price Point

The Henkelman Marlin offers long lasting quality, optimal capacity and an attractive price. Standard with CombiVAC Technology. Options like Gas flush are available to customize these vacuum sealers to your packaging needs.

POLAR

series

Single & Double Chamber Industrial Vacuum Sealers

Single and double chamber machines with extensive program & options capabilities such as gas flush, automatic lid, and customizable seal systems.

User friendly, low maintenance, and fully HACCP compliant hygienic construction.

These units are all about reliability & support — ensuring your operation stays operating.

JUMBO

series

Basic units for basic vacuum sealer needs.

Basic vacuum sealers for basic packaging needs. The Henkelman Jumbo series represent compact table-top models with ‘Jumbo’ results. Let Jumbo convince you!

Vacuum Packaging Technology

For a maximum and deep end vacuum, use a professional machine with a vacuum chamber. By extracting the air from the product, bag and chamber, the shelf life is extended and food is protected against external elements.

4 Step Vacuum Cycle

- Extraction of air

- Gas Flush (optional)

- Sealing of the bag

- Aeration

By extracting the air from the product, bag, and chamber — the product’s shelf life is extended and food is protected against external elements.

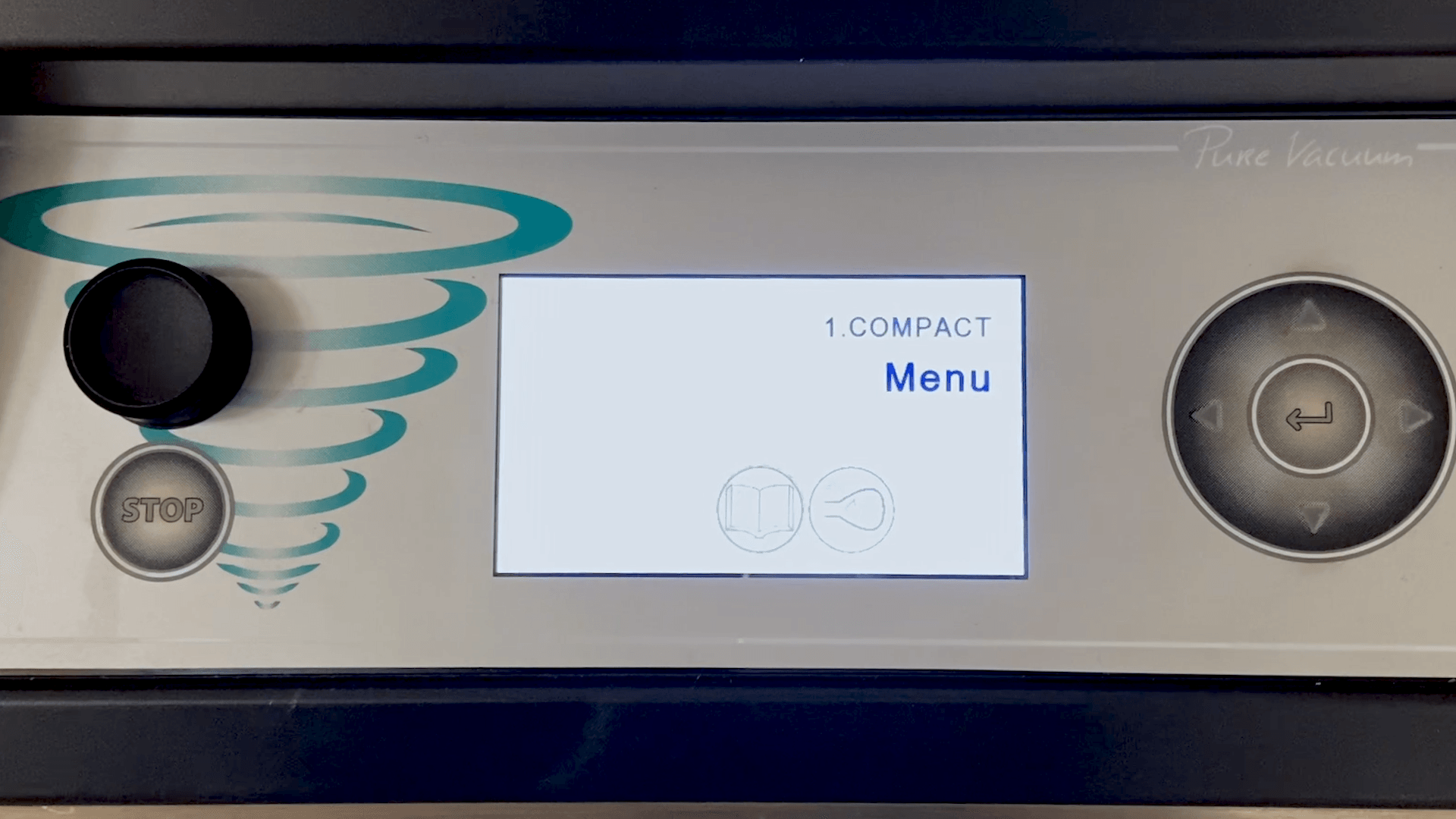

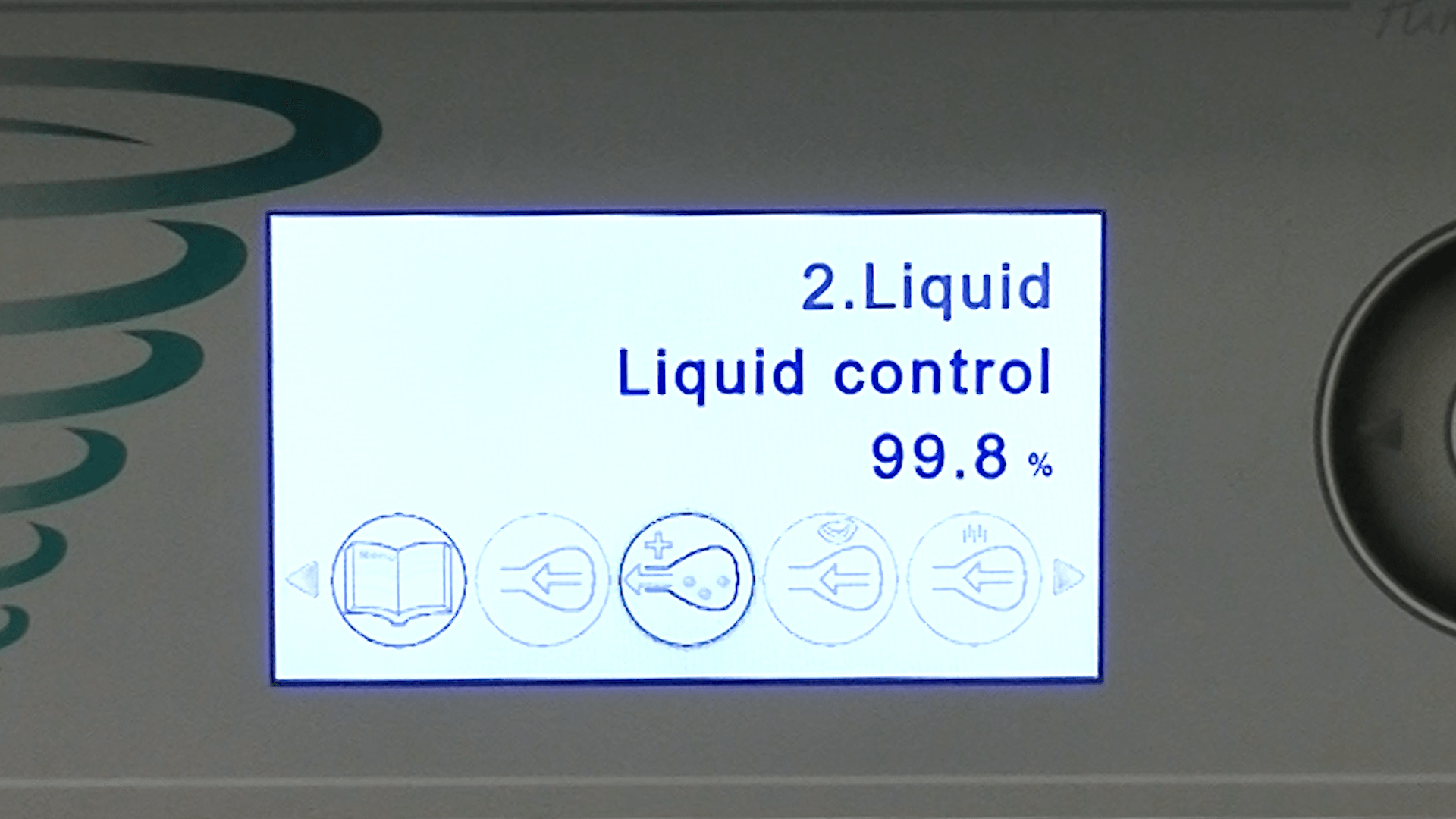

Control Systems

Control of the vacuum packaging cycle is crucial to obtain truly effective deep vacuum results.

- Time Control

- Sensor Control

- Liquid Control

Henkelman offers 3 unique control panels each with their own standard features and options to fit your application.

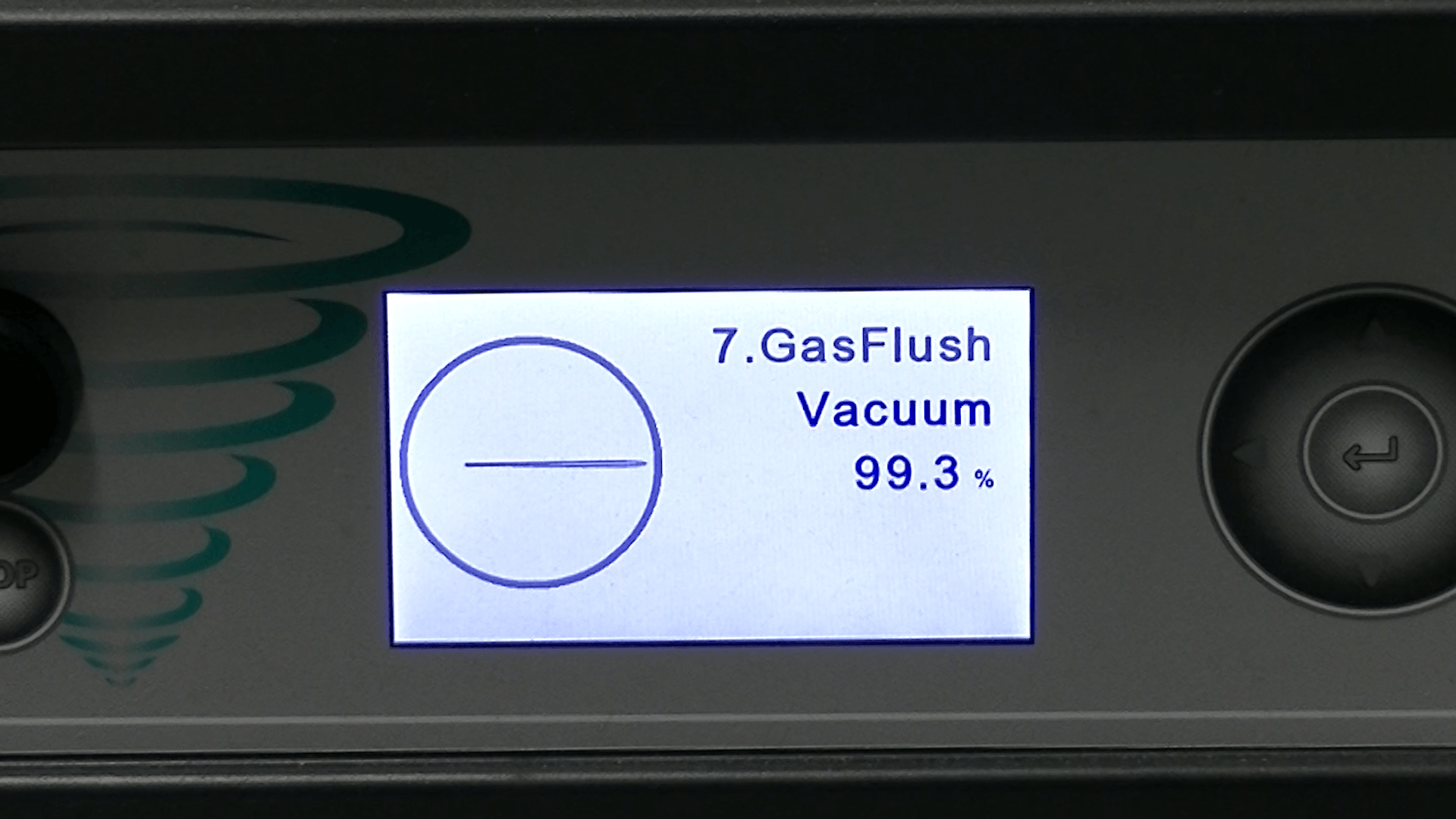

Gas Flush

Utilize the Modified Atmosphere Packaging (MAP) to achieve even greater versatility from your unit:

- Increased Shelf Life

- Eliminate “age” coloring

Usually, a mixture of nitrogen (N2) and carbon dioxide (CO2) is used. Dioxygen (O2) can also be added to this combination. The use of argon (Ar) has been increasing, as this contains the same properties as nitrogen (N2).

Seal Systems & Seal Bar Configurations

Choose a sealing solution that perfectly meets your use case.

- Standard Double Seal

- Cut-off Seal

- Wide Seal

Henkelman’s customized service delivers exactly the solution your workspace demands.

Soft Air

Soft Air allows a gradual reintroduction of air into the chamber.

Thus, making it ideal for products like T-bone Steaks, Ribs, Seafood, and Rack of Lamb.

This gradual process is based on a specified pre-set time that controls how the bag gently envelopes the product reducing the likelihood of a bag puncter or damaged product.

Maintenance Procedures:

All vacuum sealers are easy to maintain and clean. Inside and out. Preventive or whenever necessary. We have designed our equipment, especially for this purpose. Learn all about Henkelman maintenance.

Pump Maintenance

The pump is the heart of your vacuum sealer.

For that, it should be held in perfect condition. Every Henkelman machine is equipped with a pump maintenance or pump cleaning program. By extracting moisture from the pump oil, the pump is cleaned and corrosion is prevented.

The Henkelman maintenance program is easy to activate with the click of a button.

Maintenance Alert

All Henkelman control panels can be programmed to generate a maintenance alert for every random number of cycles.

When the machine has run the programmed number of cycles, the C of Conditioning starts flickering. It’s a standard feature on all Henkelman machines and is available for free.

Ask your distributor for more information or contact us.

Easy Clean Concept

Henkelman offers several smart design and construction solutions.

The deep drawn vacuum chambers in all table-top models are a good example. Every corner is easy to reach and easy to clean. Furthermore, certain models have flat work surfaces, without any cables or welding seams in the chamber. Besides, seal bars and insert plates are ease to remove, and the stainless steel housing facilitates quick and easy cleaning.

Service Kits

All kits include seal wires, Teflon tape and Teflon band, a lid gasket, oil for the pump, and a silicone profile for the contra bar.

Oil for pump is not included with Marlin & Polar kits.

Henkelman service kits come standard with the machines and are available as an after-sales part.

Technical Support

For parts inquiries and/or warranty issues on table-top models and Marlin 52, please contact the Parts Town hotline 1-800-458-5593 or Tech Support 1-877-592-3229.

For technical support on your Polar machines, please contact team Henkelman USA directly.

Warranty

Register your vacuum sealer for warranty and enjoy our world-renowned support.